PPE: How to 3D print your own protective equipment – April

Have you been looking rather sadly at your plastic pinny and face mask wondering how it could possibly protect you? One man thought he could fix that problem; Josef Prusa, the founder of a 3D printing company, Prusa Printers. After an intensive weekend of designing and prototyping, his team had created a model that could be distributed to health care workers around the world within days.

3D printers allow you to bring computer modelled objects into the real world and make anything you can envisage. Josef had his face shield uploaded to the internet as an open source design and it could be printed and distributed globally within hours.

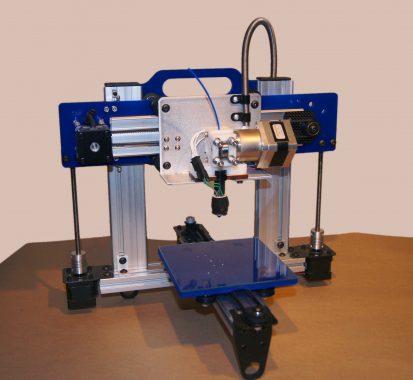

What is a 3D printer?

Looking a little like a sewing machine, a giant spool of plastic thread feeds into a heated nozzle which dances across a plate in 3 dimensions, laying the molten plastic down to form the object. File sharing sites host a variety of designs and they are small enough to be attached to an email.

Can you do this in practice as a UK GP?

One morning I was worrying about having some decent eye protection and thought to check if anyone had released any designs I could use. A Facebook post on a community site later and I had a face shield printed and in my hands the same day. At the end of the week we had donated over 150 to practices in Surrey, local district nursing teams and nursing homes – all paid for by our generous community.

Tips for making face shields

Do it yourself:

1. Get yourself a printer. A good starter mode such as an Anycubic Mega Zero can be had for £250.

2. You’ll need some filament, the plastic thread that feeds into the machine from a reel –most take 1.75mm gauge, there are different plastic types but most will work. A 1Kg reel costs around £20 and could produce 5-10 visors depending on the pattern used.

3. Find your printing pattern. Thingiverse has pretty much everything you can ever dream of, or try Josef Prusa’s original design. Anything goes and you can print items such as a door opener to keep your hands clean, a respirator mask for the more adventurous or even an adaptor to turn a snorkel into a filtered full face mask

4. The model files need something to translate them into printer-speak; the printer needs to understand how to print each layer and instructions such as the thickness each slice. These are not embedded in the model files, which are essentially just a 3d picture. Ultimaker Cura is free and intuitive, letting you import the models and export them quickly as a printer file with minimal fuss.

5. Read the setup manual, and practice! It takes a few goes to get things like the bed levelled and the first few prints may not be great. There are great communities on Twitter and Facebook that can help if you get stuck

Local community help

This is likely to be the quickest route to having a visor in your hands as there are many people who print as a hobby around the country. Reaching out on social media can lead to a remarkable swell of support – so far more than 80,000 shields have been produced this way

1. Make sure you have a file of what you need ready – responses can come quickly and you’ll want to include it in your post.

2. Think about how you want to ask for help – if you are posting from a surgery account it is crucial to mention your healthcare connections to generate some interest.

3. Consider funding or crowd funding materials – while many will donate for free, it is not a no cost item to make and you will get more volunteers this way

4. Run social media campaigns to show people the results of your work – this says thanks to your contributors, raises funds if you are crowdfunding and it pulls in more contributing printers.

Good luck! If you need any help getting going with your own campaign you can find me @dave_dlt on Twitter.

Pulse July survey

Take our July 2025 survey to potentially win £1.000 worth of tokens